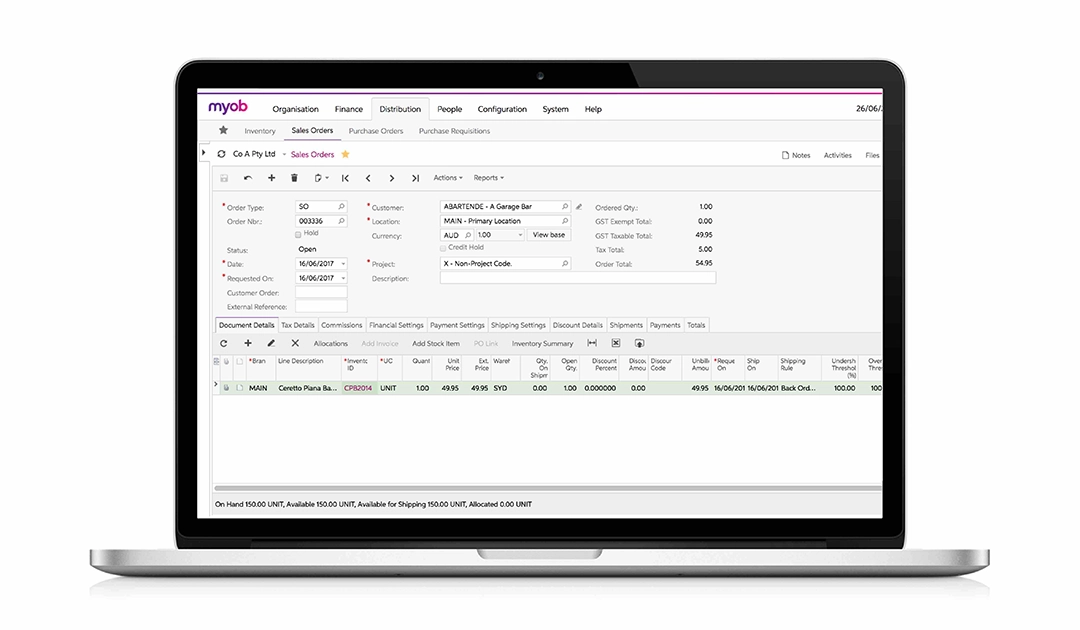

Inventory Management Software – MYOB Acumatica (formerly MYOB Advanced) Module

MYOB Acumatica (formerly MYOB Advanced) Inventory Management software provides real-time access to available inventory, inventory in transit, reorder quantities, and inventory costs, allowing you to efficiently manage your distribution process and prioritise customer satisfaction while building profitable, sustainable systems.

Smarter inventory control starts advanced Supply Chain Management functionalities!

The cloud inventory management software is a key component of the MYOB Acumatica (formerly MYOB Advanced) Supply Chain Suite, it integrates seamlessly with

- Financial Management Suite module

- Order Management module

- Purchasing Management module

Learn more about the Software here or enter your details on the right to access your FREE demo.

Software Demo

Fill the form below to get instant access to the MYOB Acumatica (formerly MYOB Advanced) demo.

One Cloud-based Software, all of your Business

Simply, connect and scale further with MYOB Acumatica (formerly MYOB Advanced). Discover how other businesses just like yours are leveraging the software.

- One, integrated solution to run all your business

- User-friendly, scalable and cost effective

- Simplified pricing and enhanced functionalities

Features of the Inventory Management Software Module in MYOB Acumatica (formerly MYOB Advanced)

Multiple Valuation Methods

The MYOB Acumatica (formerly MYOB Advanced) Inventory software allows you to value inventory using standard cost, moving average, FIFO, and item-specific methods, select different valuation methods for each inventory item, and report up-to-date valuations with unique report and inquiry screens. With valuable information kept current and synchronised across systems in the cloud, you can make direct adjustments to cost and physical inventory count.

Multiple Warehouses

MYOB Acumatica (formerly MYOB Advanced) allows you to manage multiple warehouses with location-specific inventory quantities, allocations, and costs. For each warehouse, specify the access rights to determine who can access warehouse information and enter inventory transactions. Trace inventory valuation in the General Ledger, and assign multiple warehouses to specific inventory accounts.

Lot and serial numbering

MYOB Acumatica (formerly MYOB Advanced) Inventory management works with lot and serial numbering to track inventory. Lot and serial numbers can be assigned or entered manually when you receive, issue, or assemble inventory items. Serial numbers can be linked with item-specific valuation methods to account for the cost of inventory per lot or serial number. Inquiry screens and reports allow you to view the item’s history.

Need more for your business?

More features of the Inventory Management software

Inventory Subitems: With MYOB Acumatica (formerly MYOB Advanced), separate items into sub-categories to track inventory characteristics such as size, color, and style. Associate separate cost and quality information with each subitem, and view inventory management software reports and inquiry screens to see detailed segment information, as well as aggregated inventory totals.

Expiration Dates: Assign an expiration date for each lot and serial number so expired items can be deducted from the available inventory. MYOB Acumatica (formerly MYOB Advanced) can automatically issue items with the earliest expiration date to minimize losses. Reports and inquiry screens allow you to monitor expiring items.

Negative Inventory: MYOB Acumatica (formerly MYOB Advanced) shows a negative inventory balance for an individual item or group of items. Over-issued items will use the most recent historical cost until the item is received. When received, the inventory management software will match receipt cost with issue cost and generate a cost adjustment for the difference. Negative quantities and values may apply to one site or location while aggregated inventory is positive. Notifications identify transactions that will result in negative inventory.

Two-Step Transfers: MYOB Acumatica (formerly MYOB Advanced) completes inventory transfers in two steps so you can track goods in transit between locations. The first step deducts inventory from the warehouse of origin and increases the Goods in Transit general ledger account. When goods are received, the “Goods in Transit” general ledger account is reduced and the destination site quantity and value is increased.

Inventory and Warehouse Security: User settings in MYOB Acumatica (formerly MYOB Advanced) let you control which users and roles can view and create transactions for inventory items and inventory warehouses in order to improve accuracy of data entry and simplify inventory control.

Audit Trail: MYOB Acumatica’s inventory management software provides a complete audit trail of all inventory transactions; after a transaction is released it cannot be deleted. To correct mistakes, a transaction correction entry is the only way to reverse the incorrect entry. The system keeps details of all inventory transactions, including entries and modifications by user. The result is a simplified audit process, made clearer with notes, accurate information, and supporting documents attached directly to transactions.

Check the other modules

General Ledger

Cash Management

Accounts Receivable

Accounts Payable

Employee Portal

Currency Management

%3

Recent Comments